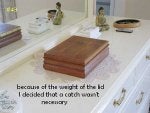

A jewellery box like this should be well within the capabilities of all but the newest member without any woodworking experience, it uses plain mitred joints made in a way that requires very little skill. The finish was six coats of Shellac, chosen because of it's very fast drying, and was completed by rubbing down with fine wire wool lubricated with mineral oil which left a nice smooth, almost antique finish. The size of the box, which was dictated by the size of the wood blocks that I had is 9" x 6" x 2.25" high. I think that the large number of photographs should make construction self explanatory.

A jewellery box for beginners

harrysin

Discussion starter

15,066 posts

·

Joined 2007

- Add to quote Only show this user

A jewellery box like this should be well within the capabilities of all but the newest member without any woodworking experience, it uses plain mitred joints made in a way that requires very little skill. The finish was six coats of Shellac, chosen because of it's very fast drying, and was completed by rubbing down with fine wire wool lubricated with mineral oil which left a nice smooth, almost antique finish. The size of the box, which was dictated by the size of the wood blocks that I had is 9" x 6" x 2.25" high. I think that the large number of photographs should make construction self explanatory.

Attachments

-

33.2 KB Views: 652

-

46 KB Views: 509

-

45.1 KB Views: 507

-

39.7 KB Views: 473

-

32.3 KB Views: 445

-

40.6 KB Views: 461

-

34 KB Views: 469

-

63.4 KB Views: 477

-

64.5 KB Views: 466

-

35.6 KB Views: 414

-

55.3 KB Views: 425

-

34.9 KB Views: 436

-

41.7 KB Views: 396

-

30.1 KB Views: 370

-

49.4 KB Views: 464

-

37.9 KB Views: 501

-

42 KB Views: 431

-

48.5 KB Views: 417

-

47.7 KB Views: 425

-

50.1 KB Views: 471

harrysin

Discussion starter

15,066 posts

·

Joined 2007

We now continue with the assembly of the box and end with two shots of the wood that I was given some time ago, allegedly Sheoak but it turned out to be Banksia.

Attachments

-

36.8 KB Views: 359

-

40.7 KB Views: 325

-

44.5 KB Views: 331

-

26.4 KB Views: 253

-

35.9 KB Views: 310

-

28.9 KB Views: 287

-

45.7 KB Views: 297

-

44.9 KB Views: 306

-

37 KB Views: 299

-

43.5 KB Views: 300

-

37.3 KB Views: 271

-

39.6 KB Views: 307

-

36.3 KB Views: 310

-

48.8 KB Views: 339

-

25.1 KB Views: 321

-

26.7 KB Views: 332

-

33.8 KB Views: 303

-

46.1 KB Views: 338

-

43 KB Views: 353

-

31.9 KB Views: 345

10,671 posts

·

Joined 2008

Great write up, as always, I might be able to follow this. I need it simple and your write makes it simple thanks.

harrysin

Discussion starter

15,066 posts

·

Joined 2007

Nice job Harry

But I got to ask why not just buy the lumber (molding) from the lumber yard. a 5.oo dollar item most of the time or less, do you have a inlay kit for your router to put the mirror in place quick and easy way,or a pattern bit..plus if you are going to cover the parts, in the box why not use 1/4" thick MDF/plywood lumber..

I know it's fun to making it from a log but it's like making your own hand saw, WHY.

By the way have you tried this ? real quick way

DonJer Products Soft Flock SuedeTex Product Flocking Rayon Nylon Fibers Adhesive Applicators Kits

DonJer Products Soft Flock SuedeTex Product Flocking Rayon Nylon Fibers Adhesive Applicators Kits

Projects DonJer Products Suede-Tex Soft Flock Rayon Nylon Fibers

Bob, I'm truly amazed that you would suggest BUYING anything when you have on many occasions called yourself "a cheap sob" For instance, knobs, you make your own but I buy mine. This series of projects is aimed squarely at beginners and is intended to show as many ways as possible to achieve a particular end result. I know that you wouldn't want newcomers to go through life thinking that making mouldings can only be done on a foursider! MDF or ply inside isn't a bad idea but I would know that that it wasn't a solid Banksia jewellery box that one day might be dropped by a future generation and they would think what a cheapskate their great granddad was!!

11,750 posts

·

Joined 2007

Bob,

Not answering for Harry, but your observation that "it's fun..." is reason enough for me.

Not answering for Harry, but your observation that "it's fun..." is reason enough for me.

3,136 posts

·

Joined 2008

I imagine anyone could make a box from MDF and pre-made moldings. They would be a box maker. A woodworker would craft a box from solid wood like Harry has done. That would make him a craftsman would it not? Box maker and craftsman are not the same in my books.

1,803 posts

·

Joined 2006

Harry that is a nice write up. I love the way you did the ring holders. I have had problems with that part in the past.

706 posts

·

Joined 2009

Well done Harry......said to the wife that you must be doing an instructional piece...it was all too quiet in Rockingham......once again, thanks.............AL

477 posts

·

Joined 2008

Hi Harry,

Great wip and tutorial as always. If I lived closer I would drop over and liberate a few pieces of that Banksia.

Regards

Harold

Great wip and tutorial as always. If I lived closer I would drop over and liberate a few pieces of that Banksia.

Regards

Harold

11,750 posts

·

Joined 2007

Banksia is a new one for me.....I don't get out much.....It sure looks good in those slab photos, though.

What sort of wood is it? What sort of tree is it? Is the wood used much down under?

What sort of wood is it? What sort of tree is it? Is the wood used much down under?

777 posts

·

Joined 2009

Nice tutorial harry, and I must say you must look good in that jewelry

All everyone needs to know about Banksia.

Banksia - Wikipedia, the free encyclopedia

As children in Australia you grow up with stories of the Banksia men trying to get you when you walk through the bush.

![Image]()

Bob, you can't buy off the shelf Banksia wood, and why spend money on mdf when you have free banksia ?

All everyone needs to know about Banksia.

Banksia - Wikipedia, the free encyclopedia

As children in Australia you grow up with stories of the Banksia men trying to get you when you walk through the bush.

Bob, you can't buy off the shelf Banksia wood, and why spend money on mdf when you have free banksia ?

harrysin

Discussion starter

15,066 posts

·

Joined 2007

Thank you Gavin for that information, here is a shot of some Banksia nuts in my wood shed, all of the wood has been given for FREE, that I hope one day to make something out of on the lathe. The only time that I tried to turn one I wasn't suitably dressed for the huge amount of debris that completely covered me and blunted my gouge.Nice tutorial harry, and I must say you must look good in that jewelry

All everyone needs to know about Banksia.

Banksia - Wikipedia, the free encyclopedia

As children in Australia you grow up with stories of the Banksia men trying to get you when you walk through the bush.

![Image]()

Bob, you can't buy off the shelf Banksia wood, and why spend money on mdf when you have free banksia ?

My thanks to you all for your welcome comments.

Attachments

-

50.3 KB Views: 134

219 posts

·

Joined 2009

Harry,

As always, and excellent write up. I think I will add this to the pdf list. One thing I am curious about. All of your pictures and write ups are always so detailed, but the other day it dawned on me, you never state what speed you are running the router out. I am a newbie at this, and I always wonder what speed the router should be run at for a given bit. I know there are charts with recommended speeds for different size bits, but since these are tutorials, I thought that would be a nice touch.

I know, I know, just something else to have to remember.

My goal is to make items out of rough stock, mainly trees that I have cut down myself. I do not have the means to cut long tree trucks so most of the items would be small, like trivets, cutting boards and box. This is the main reason I am building skis, so I can plane down one side flat before running it through the planer and truing it up.

Keep up the great work, and I hope you get your voice back soon.

Darrin

As always, and excellent write up. I think I will add this to the pdf list. One thing I am curious about. All of your pictures and write ups are always so detailed, but the other day it dawned on me, you never state what speed you are running the router out. I am a newbie at this, and I always wonder what speed the router should be run at for a given bit. I know there are charts with recommended speeds for different size bits, but since these are tutorials, I thought that would be a nice touch.

I know, I know, just something else to have to remember.

My goal is to make items out of rough stock, mainly trees that I have cut down myself. I do not have the means to cut long tree trucks so most of the items would be small, like trivets, cutting boards and box. This is the main reason I am building skis, so I can plane down one side flat before running it through the planer and truing it up.

Keep up the great work, and I hope you get your voice back soon.

Darrin

harrysin

Discussion starter

15,066 posts

·

Joined 2007

I will appreciate you performing your magic once again Darrin. As for router speed, hand held I don't use huge cutters so the speed is left full on, with the table, for all by very large cutters I again leave it at full speed but drop down to about #3 on a scale of 1 to 5. I've never been pedantic regarding router and lathe speeds but do take more care with my milling machine so as not to stress it. Perhaps this laid back attitude to speed doesn't set a good example to beginners, but I really haven't ever had cause for concern.

1,803 posts

·

Joined 2006

Harry, dose that tree you used have any historical value? We have trees here on the island that have been here since before George Washington was around. At the William Floyd estate you can still see the horse shoe prints from the British horses on the floor. The British took over William Floyd's house during the revolutionary war. William Floyd signed the declaration of independent for those who were not required to learn American history. Can you see me making a blanket chest out of those floor boards? Then being arrested by the federal,park police for destruction of a national monument.

harrysin

Discussion starter

15,066 posts

·

Joined 2007

Not so far as I know John, the tree was cut down in the grounds of where my son works and brought to me by my granddaughters husband who also works there, I assume that it was becoming dangerous. Populated Australia is too young to have much history, by that I mean European population.

777 posts

·

Joined 2009

Dang Harry, I can't believe you're younger than my mother and yet you have a granddaughter that has a husband !?

My mind boggles.

My mind boggles.

2 posts

·

Joined 2009

Thanks

Just wanted to say thanks for the tutorial. I especially likes showing the mistake and correction. Something missing from most.

I really like your collection of clamps.

Lynn

Just wanted to say thanks for the tutorial. I especially likes showing the mistake and correction. Something missing from most.

I really like your collection of clamps.

Lynn

4 posts

·

Joined 2010

Thanks so much for all your work to create this posting. Very informative and useful. I do have a question about the bottom- isn't there a danger of the solid wood bottom breaking the box if there are swings in humidity (since it is glued in all around)?

harrysin

Discussion starter

15,066 posts

·

Joined 2007

Whilst that is only one of several methods that I use Bill, I still have boxes made ten years ago using that method with no obvious problems. I do make the bottom a relatively loose fit allowing glue to fill gaps, then glue felt on the bottom.

193 posts

·

Joined 2010

Really nice work. I would never have thought of routing a large piece and then slicing into boards. The zip file at the end will make it easy to construct a slide show to use when doing it myself.

Thanks for your contribution.

Thanks for your contribution.

33 posts

·

Joined 2008

At the risk of sounding critical, which is not my intention as this is a fine write-up containing a wealth of useful information, but I have to ask the question, is the term "beginner" in the title really appropriate given that the methodology makes use of such a lot of expensive machinery that a beginner is unlikely to own or have access to?

In particular I refer to the use of:

1) bandsaw

2) planer

3) disk sander

I would have thought you would be unlikely to find these items in a beginners workshop as they are $500+ items (possible exception being the disk sander).

Is resawing really an option for the beginner?

In particular I refer to the use of:

1) bandsaw

2) planer

3) disk sander

I would have thought you would be unlikely to find these items in a beginners workshop as they are $500+ items (possible exception being the disk sander).

Is resawing really an option for the beginner?

16,386 posts

·

Joined 2010

Gary,

Every woodshop has to have at the very least a tablesaw. It will resaw timbers. If it is a 10", it will resaw a 6" timber. You can flatten the backside of the pieces by sanding or with a router on skis. You can cut accurate miters with a chop saw or your table saw and you don't have to worry about shatter or blowout if you use a sacrificial fence behind the piece.

I never made a really accurate mitre until I bought a set of blade stabilizers, essentially a much larger and stiffer washer. Mine are Dimar and cost about $25. They help on a chop saw or tablesaw especially if you don't want to spend huge amounts of money on blades. You should be able to do what Harry did but with a little more effort and elbow grease.

Every woodshop has to have at the very least a tablesaw. It will resaw timbers. If it is a 10", it will resaw a 6" timber. You can flatten the backside of the pieces by sanding or with a router on skis. You can cut accurate miters with a chop saw or your table saw and you don't have to worry about shatter or blowout if you use a sacrificial fence behind the piece.

I never made a really accurate mitre until I bought a set of blade stabilizers, essentially a much larger and stiffer washer. Mine are Dimar and cost about $25. They help on a chop saw or tablesaw especially if you don't want to spend huge amounts of money on blades. You should be able to do what Harry did but with a little more effort and elbow grease.

16,386 posts

·

Joined 2010

Beautiful Job Harry,

I've never heard of banksia so I googled it. According to the article I read it is a gnarly shrub that can occasionally grow to as much as 15m tall in certain areas of Australia. If that's true then I would imagine the piece you showed is fairly special and that it is not a commercially viable species. It is really attractive, interesting grain and beautiful color.

I've never heard of banksia so I googled it. According to the article I read it is a gnarly shrub that can occasionally grow to as much as 15m tall in certain areas of Australia. If that's true then I would imagine the piece you showed is fairly special and that it is not a commercially viable species. It is really attractive, interesting grain and beautiful color.

harrysin

Discussion starter

15,066 posts

·

Joined 2007

Charles, whilst I've been familiar with Banksia trees since buying our second house in Australia a couple of days before Christmas day in 1967 because one had been left standing in the corner of the back garden, I've never heard of it being sold commercially. I have plenty left so hope to come up with a variety of projects using it.

23 posts

·

Joined 2010

Very nice tutorial, Harry!! Beautiful box, I'm sure you got a big smooch on the cheek and hug from some happy girl in your family!!!

Did you do the rough sawing yourself? If so, how and did you worry about moisture content before working with it?

Just curious, because I have some walnut and cherry logs a couple friends have given to me and want to start using them. I have been reading about resawing, air drying etc.... but I'm nowhere ready to start doing it.

Regards,

Tim

Did you do the rough sawing yourself? If so, how and did you worry about moisture content before working with it?

Just curious, because I have some walnut and cherry logs a couple friends have given to me and want to start using them. I have been reading about resawing, air drying etc.... but I'm nowhere ready to start doing it.

Regards,

Tim

harrysin

Discussion starter

15,066 posts

·

Joined 2007

It hasn't yet been decided who will get it. The log was far too heavy for me to handle but fortunately I have a good friend who lives quite close and I took it to him and was amazed at how easy he made it look rolling it off the trailer. He has a collection of chain saws and a BIG band saw so the next time I saw the "log" it was as shown in the photo at the end of the thread, not only cut up but all the ends dipped in wax. I have a woodshed where I left it for probably a year. I do have a digital moisture meter whereas purists like Bernie weigh the wood from time to time.

harrysin

Discussion starter

15,066 posts

·

Joined 2007

At the risk of sounding critical, which is not my intention as this is a fine write-up containing a wealth of useful information, but I have to ask the question, is the term "beginner" in the title really appropriate given that the methodology makes use of such a lot of expensive machinery that a beginner is unlikely to own or have access to?

In particular I refer to the use of:

1) bandsaw

2) planer

3) disk sander

I would have thought you would be unlikely to find these items in a beginners workshop as they are $500+ items (possible exception being the disk sander).

Is resawing really an option for the beginner?

Gary, a good question, however, my reason for producing this series is not so much to have beginners set about making these projects, rather my intention is to demonstrate different methods of achieving a particular result. In the case of this jewellery box, it's the first time that I have made moulding in this way, in the past I have used 2" x 1" across the moulding cutter.The one in this shot that I made about eight years ago, using the same cutter was made this way for my daughter-in-law. Hopefully these threads will also give newcomers a better idea of what machine tools to aim for as money becomes available.

In particular I refer to the use of:

1) bandsaw

2) planer

3) disk sander

I would have thought you would be unlikely to find these items in a beginners workshop as they are $500+ items (possible exception being the disk sander).

Is resawing really an option for the beginner?

Gary, a good question, however, my reason for producing this series is not so much to have beginners set about making these projects, rather my intention is to demonstrate different methods of achieving a particular result. In the case of this jewellery box, it's the first time that I have made moulding in this way, in the past I have used 2" x 1" across the moulding cutter.The one in this shot that I made about eight years ago, using the same cutter was made this way for my daughter-in-law. Hopefully these threads will also give newcomers a better idea of what machine tools to aim for as money becomes available.

Attachments

-

43.4 KB Views: 122

777 posts

·

Joined 2009

Never fear Gary, I am in the process of making a jewellery box that absolute beginners can make using only electric hand tools. I know that beginners can make it because many of the techniques I am using are a first for me and I consider myself a beginner.

You'll probably have to wait until after christmas, but when I finally put it up, you'll see me cutting the dead tree down, milling the wood in the most basic way and making a box from it.

Ok, couldn't resist a teaser but I will be starting my own thread when the job is finished.

Here's a pic of the tree ( just a stump now) I started with that was growing on the property I grew up in when my parents bought the land in Ipswich Australia, 1966. On my recent visit they asked me to chop some down. I decided to bring some of it back to Croatia with me and make something out of it.

You'll probably have to wait until after christmas, but when I finally put it up, you'll see me cutting the dead tree down, milling the wood in the most basic way and making a box from it.

Ok, couldn't resist a teaser but I will be starting my own thread when the job is finished.

Here's a pic of the tree ( just a stump now) I started with that was growing on the property I grew up in when my parents bought the land in Ipswich Australia, 1966. On my recent visit they asked me to chop some down. I decided to bring some of it back to Croatia with me and make something out of it.

33 posts

·

Joined 2008

Can't wait Gav, in particular I will be interested in seeing how you flatten/smooth the wood - but please don't make me get my old hand plane out...:fie:Never fear Gary, I am in the process of making a jewellery box that absolute beginners can make using only electric hand tools. I know that beginners can make it because many of the techniques I am using are a first for me and I consider myself a beginner.

You'll probably have to wait until after christmas, but when I finally put it up, you'll see me cutting the dead tree down, milling the wood in the most basic way and making a box from it.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 760K

- members

- 137K

- Since

- 2004

A forum community dedicated to router and woodworking professionals and enthusiasts. Come join the discussion about different types of routing and routers, shop safety, finishing, woodworking related topics, styles, tools, scales, reviews, accessories, classifieds, and more!

Top Contributors this Month

View All

DesertRatTom

160 Replies

old55

95 Replies

BladesNBarrels

66 Replies