To a large extent this is somewhat funny, if not pathetic. Yet somehow interesting.

here is a short list of established, well credentialed sources who make no distinction between box and finger joint.

Simply put, the two terms are quite often interchangeable.

WoodWorkers Guild of America;

Woodworking Joints: Which One Should You Use

Gary Rogowski: The Complete Illustrated Guide to Joinery (A standard in joinery literature);

The Complete Illustrated Guide to Joinery by Gary Rogowski - Complete Illustrated Guide Series - Woodworking - Techniques - Hardcover Book - Taunton Store

Wikipedia:

https://en.wikipedia.org/wiki/Woodworking_joints

ShopSmith:

Incra I-Box? Comparison To Convention Box Joint Method

LeeValley:

Incra® I-Box Finger Joint Jig - Lee Valley Tools

Leigh joinery jigs:

https://www.leighjigs.com/super_fingers.php

FineWoodworking:

Multi-Purpose Tablesaw Jig - Fine Woodworking Interactive

Now, I have no names to drop and I certainly don't pretend to have any industry contacts to reference, but

what I do got is common sense. And that is what the members need to use. Just a lil common sense. This

clearly if not definitively illustrates that a common joint may be referred to by various names. The names may

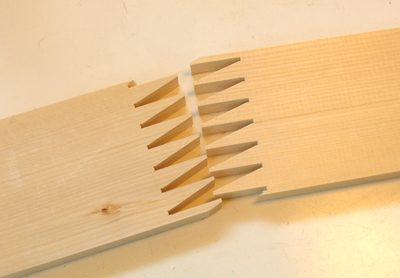

be local, regional or even national, this does not mean they are universal and absolute. A tapered finger joint

is completely different than a finger/box joint. Application is completely different. Yet the names of the joints

are confusingly similar.

I have always just considered a box joint a box joint and a finger joint a finger joint until this marvelous display of

editorial buffoonery. The fact is that the two can be and in many circles are just one in the same. Just because

terms and definitions were laid out in a long lost glossary don't mean they were/are correct. All it means is that the

author of the definitions believed it to be a certain way or to have fit within certain criteria. Inquires like answers are not always

black and white, one person and/or source should not be expected to be the definitive source of all things wood working.

As is said quite often in here, there is more than one way to skin a cat, and at least a couple dozen ways telling you how to do it.