New user here, looking for tips from someone more experienced about how to use a template and guide bushing without damaging the workpiece.

I am trying to make the Ron Paulk Total Station workbench. It requires routing several large rectangular holes, about 18" by 6", with round ends, using a template and guide bushings.

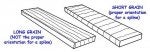

So far, I have ruined three templates and three workpieces. It seems that while rounding the six inch diameter half circles, the router leaves the template and gouges the template or the workpieces. I can't seem to get the hang of how to keep the router down against the template while also pressing it toward the template as it goes around the curve. The harder I try to push down and toward the template, the more likely the router is to jump. But, if I don't push down and toward the template, the router walks inward away from the template.

Is the guide bushing depth of about (3/16") is too short for the template depth of 1/2"?

Would making the template thinner (1/4") help? Or thicker (3/4") and switching the guide bushing to the longer one (9/16")? I think if I go thicker then my bit won't reach all the way through the workpiece and I'll have to rout from both sides. Not sure I can do this and keep everything aligned.

Do I need to keep the same side of the router facing the template as I go around the curve?

I am also wondering if putting some template wood in the center of the oval template would help, to keep the router from tipping toward the center?

I am to the point where I am trying to figure out how to make the workbench without using a router, since I am so bad at it.

I would consider buying a better router like the Bosch 1617 but only have the budget right now for the workbench, not for the router.

Thanks in advance for any suggestions. I am new to woodworking and want to get past this frustrating learning curve.

BTW, I tried to include URL's for the project and the guide bushings but the forum won't let me until I make 10 posts(?)

Project: Ron Paul Total workstation

Router: Skil 1835 (inherited from Dad)

Template router base and bushings: Milescraft 1201

Router bit: 1/2" straight cut

I am trying to make the Ron Paulk Total Station workbench. It requires routing several large rectangular holes, about 18" by 6", with round ends, using a template and guide bushings.

So far, I have ruined three templates and three workpieces. It seems that while rounding the six inch diameter half circles, the router leaves the template and gouges the template or the workpieces. I can't seem to get the hang of how to keep the router down against the template while also pressing it toward the template as it goes around the curve. The harder I try to push down and toward the template, the more likely the router is to jump. But, if I don't push down and toward the template, the router walks inward away from the template.

Is the guide bushing depth of about (3/16") is too short for the template depth of 1/2"?

Would making the template thinner (1/4") help? Or thicker (3/4") and switching the guide bushing to the longer one (9/16")? I think if I go thicker then my bit won't reach all the way through the workpiece and I'll have to rout from both sides. Not sure I can do this and keep everything aligned.

Do I need to keep the same side of the router facing the template as I go around the curve?

I am also wondering if putting some template wood in the center of the oval template would help, to keep the router from tipping toward the center?

I am to the point where I am trying to figure out how to make the workbench without using a router, since I am so bad at it.

I would consider buying a better router like the Bosch 1617 but only have the budget right now for the workbench, not for the router.

Thanks in advance for any suggestions. I am new to woodworking and want to get past this frustrating learning curve.

BTW, I tried to include URL's for the project and the guide bushings but the forum won't let me until I make 10 posts(?)

Project: Ron Paul Total workstation

Router: Skil 1835 (inherited from Dad)

Template router base and bushings: Milescraft 1201

Router bit: 1/2" straight cut