About one month before Christmas, I decided to make and give to my relatives and friends about 15 cheeseboards made from ends and offcuts of cypress planks that I use for my hobby furniture making.

Cypress looks very much like pine; when polished or stained it is not easy for everyone to say what is pine and what is cypress. Working with it, I found that it is much harder and heavier than pine, and its major drawback is that it splits, just like that, impossible to tell where and when it will. Sawing or routing or sanding it, its resins give an aromatic odour that stays with it for a long time.

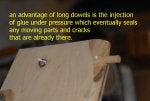

I happened to have access to big planks of cypress, and solved the problem of splitting with long dowels, 10mm diam., that go into the wood for 6 - 24 cm. A simple drill jig and a lot of practice, trial anderror, and I am finally happy withthe method and the results.

So, I figured that I could shape some plank ends and give them as cheeseboards to friends and colleagues. And then I thought, if I turn the board over and carve 3 dished areas, avbig one for nuts and two small ones for liqueur (or raki or gin), it will be even better. So I posted a thread:

http://www.routerforums.com/router-bits-types-usage/31492-what-dishing-bits-there.html

and got a lot of very interesting ideas and suggestions but followed noe for various purposes.

So I made two small pits for glasses on the back of each one and gave about 22 of those away. After the final sanding I soaked them in olive oil - no trade polishes, as they are used for putting edible stuff on them.

Here is some pictorial description and evidence:

Cypress looks very much like pine; when polished or stained it is not easy for everyone to say what is pine and what is cypress. Working with it, I found that it is much harder and heavier than pine, and its major drawback is that it splits, just like that, impossible to tell where and when it will. Sawing or routing or sanding it, its resins give an aromatic odour that stays with it for a long time.

I happened to have access to big planks of cypress, and solved the problem of splitting with long dowels, 10mm diam., that go into the wood for 6 - 24 cm. A simple drill jig and a lot of practice, trial anderror, and I am finally happy withthe method and the results.

So, I figured that I could shape some plank ends and give them as cheeseboards to friends and colleagues. And then I thought, if I turn the board over and carve 3 dished areas, avbig one for nuts and two small ones for liqueur (or raki or gin), it will be even better. So I posted a thread:

http://www.routerforums.com/router-bits-types-usage/31492-what-dishing-bits-there.html

and got a lot of very interesting ideas and suggestions but followed noe for various purposes.

So I made two small pits for glasses on the back of each one and gave about 22 of those away. After the final sanding I soaked them in olive oil - no trade polishes, as they are used for putting edible stuff on them.

Here is some pictorial description and evidence: