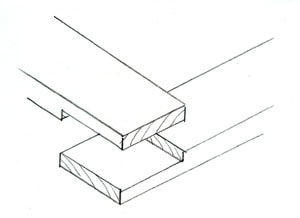

Hi, I need to be able to repeatedly and precisely make holes for dowels to joint 2 pieces of wood in the way the picture shows:

![Image]()

I didn't come out with a method for this yet, I thought of building some kind of structure with predrilled holes, then push the piece of wood there and drill with some kind of stop.. but.. not sure.

Any ideas?, do I need to have a drill bank for this?, I don't, but if required I could get one I guess.

(btw, if you think of a better way to joint this, let me know!, for the moment is only glued, the structure is only used for a picture frame, so is not required to be strong, but, the stronger the better I guess.)

I didn't come out with a method for this yet, I thought of building some kind of structure with predrilled holes, then push the piece of wood there and drill with some kind of stop.. but.. not sure.

Any ideas?, do I need to have a drill bank for this?, I don't, but if required I could get one I guess.

(btw, if you think of a better way to joint this, let me know!, for the moment is only glued, the structure is only used for a picture frame, so is not required to be strong, but, the stronger the better I guess.)