So after mulling it over a bit, I decided what to do and finished the grooves this past weekend.

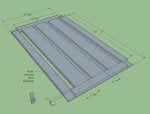

I really liked the design of the Trend/Unika Euro-style templates, so I made one by laying up 1/2" thick strips of MDF onto a piece of 1/4" MDF. I ran a 3/4" bowl bit with an upper pilot bearing along the channels, routing through the 1/4 MDF, to finish it off. This additive assembly approach allowed for true, parallel, evenly spaced channels in my template. (Come to think of it, this approach would also make it possible for a fancy pattern of converging grooves or some freeform branching pattern.)

To get my pitch, I cut a handful of thin wedges about 12" long and 1/4" at the thick end with a Rockler taper jig and secured them to the underside of the template. I went with something a little less than 1/4 a in 12". It's hard to say exactly what the pitch is because at that shallow an angle, deviations tend stack up pretty quickly.

I secured the jig and wedges to the Corian countertop with a several small pieces of 3M "Extreme" mounting tape supplemented with some of their conventional indoor double sided tape. For extra insurance, I placed a couple bearing blocks against the walls and backsplash. There is such a thing as overdoing the DST, and I pretty much ruined the template removing it after making my cuts.

The 3/4" bowl bit I used had 1/4" radii at the edges, so with 2 passes, I cut a nice looking, 1" wide groove, while bearing on a guide strip on each pass.

There was a little flex to the template before I put the wedges on, so if I was to do it again, I might lay 1/2" strips on a thicker, 1/2" flat. Hopefully, the the bit would still be long enough to protrude through resulting 1" thick template and still have a useful depth of cut. Also, I think I'd make the template longer and wider to allow areas for clamps that wouldn't interfere with the router base.

![v144-0702_p[1].jpg](/d3/attachments/33/33747-74e83ec14e2bcb348a8834144e4ae2f9.jpg)