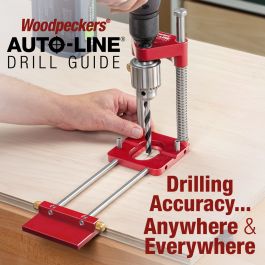

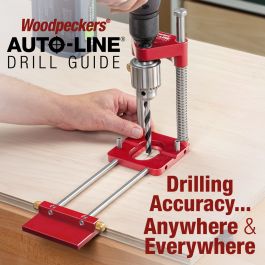

Maybe best solution for small shops.

www.woodpeck.com

Only problem it's expensive.

www.woodpeck.com

Only problem it's expensive.

But doesn't take much space.

Auto-Line Drill Guide

More videos are available in the Video tab below. There are those among us who can pick up a drill, place it on a workpiece and drill a straight hole. Then, there are the remaining 99.9% of us. A drill press solves the problem…as long as the piece you want to drill fits. But if you’re not one of...

But doesn't take much space.