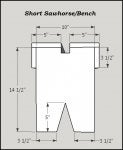

I don't know exactly what to call these. Are they saw horses, or work benches or what?

Regardless, I have a need for a pair of them. My current project is 25 x 90 x 12 inches. Sooo...I need to lay it on one side while I spray the finish, then lay it on its back to do the same.

I have some left over plywood from previous cabinet builds so I plan to cut it up and use what I can. Note the final version my vary slightly depending on what wood I have available.

They should be easy to build. Glue and drywall screws should make them sturdy enough for this job.

While I was at it, I decided to make slots so a 2x4 can sit on edge and support something that needs to be cut like plywood panels.

Note that I don't plan to ever stand on them but I might add more support later if I don't throw them away.

For storage, I made one bench narrower than the other and shorter so it will nest under to other one. Rack 'em and stack'em.

What do you think? Will they work as temporary short saw horses?

Mike

Regardless, I have a need for a pair of them. My current project is 25 x 90 x 12 inches. Sooo...I need to lay it on one side while I spray the finish, then lay it on its back to do the same.

I have some left over plywood from previous cabinet builds so I plan to cut it up and use what I can. Note the final version my vary slightly depending on what wood I have available.

They should be easy to build. Glue and drywall screws should make them sturdy enough for this job.

While I was at it, I decided to make slots so a 2x4 can sit on edge and support something that needs to be cut like plywood panels.

Note that I don't plan to ever stand on them but I might add more support later if I don't throw them away.

For storage, I made one bench narrower than the other and shorter so it will nest under to other one. Rack 'em and stack'em.

What do you think? Will they work as temporary short saw horses?

Mike