I need to round over some small pieces - 1" disks for toy wheels, small figures etc. I've got a 1/4" round-over bit with a bearing mounted in the router but I'm uneasy about getting my fingers all that close to the bit. Is there a good technique for holding these small pieces? Also, my table (a Wolfcraft) doesn't have any inserts so there is a bit of a gap between the table and the bit. Is there a good way to make an insert for a table?

fishlore

- Status

- Not open for further replies.

small pieces

fishlore

Discussion starter

31 posts

·

Joined 2007

- Add to quote

I need to round over some small pieces - 1" disks for toy wheels, small figures etc. I've got a 1/4" round-over bit with a bearing mounted in the router but I'm uneasy about getting my fingers all that close to the bit. Is there a good technique for holding these small pieces? Also, my table (a Wolfcraft) doesn't have any inserts so there is a bit of a gap between the table and the bit. Is there a good way to make an insert for a table?

2,392 posts

·

Joined 2004

I think I'd try mounting them to a carrier board using a Flat Head bolt that would sink into the wheel and not hit the table... a spacer between wheel & carrier board to allow router bit room...

Then using a bearing router roundover bit... where bearing would hit center of wheel (I trust the wheel disk is round & smooth)... Adjust the bit... and run the wheels around the bit... dismount wheel & turn it over for other side...

Make sense?

Then using a bearing router roundover bit... where bearing would hit center of wheel (I trust the wheel disk is round & smooth)... Adjust the bit... and run the wheels around the bit... dismount wheel & turn it over for other side...

Make sense?

23,784 posts

·

Joined 2006

Hi Fihlore

The router may not be the right tool to do this job,, 1" dia. are very small..

1" dia. are very small..

This is what I do when I need to round over Small wheels

Insert a 1/4 bolt into the wheel with a washer on bolt and then put on a nut and lock the nut in place then chuck up the bolt in your battery drill motor and take it to your sander or if you don't have a bench sander clamp one of your hand sander in a vise, then lock it on and put the wheel to the sander,, they will come out clean and with just the right round over, try it 1st. with a test wheel once you have it down then do the rest of them...

===========

The router may not be the right tool to do this job,,

This is what I do when I need to round over Small wheels

Insert a 1/4 bolt into the wheel with a washer on bolt and then put on a nut and lock the nut in place then chuck up the bolt in your battery drill motor and take it to your sander or if you don't have a bench sander clamp one of your hand sander in a vise, then lock it on and put the wheel to the sander,, they will come out clean and with just the right round over, try it 1st. with a test wheel once you have it down then do the rest of them...

===========

fishlore said:I need to round over some small pieces - 1" disks for toy wheels, small figures etc. I've got a 1/4" round-over bit with a bearing mounted in the router but I'm uneasy about getting my fingers all that close to the bit. Is there a good technique for holding these small pieces? Also, my table (a Wolfcraft) doesn't have any inserts so there is a bit of a gap between the table and the bit. Is there a good way to make an insert for a table?

168 posts

·

Joined 2007

Hi Fish -

That's good advice from Joe and Bob. Keep your fingers away from those bits !

Also, if you have a lathe, that might be another way to make them. If you're not opposed to buying them, do a search on "Wood Toy Wheels" and you'll get lots of hits. Here's the first one I found:

http://www.craftparts.com/mall/page38.asp

..most any kind you can think of. Post some photos of your projects for us.

Good luck.

Roger

(Roefa)

That's good advice from Joe and Bob. Keep your fingers away from those bits !

Also, if you have a lathe, that might be another way to make them. If you're not opposed to buying them, do a search on "Wood Toy Wheels" and you'll get lots of hits. Here's the first one I found:

http://www.craftparts.com/mall/page38.asp

..most any kind you can think of. Post some photos of your projects for us.

Good luck.

Roger

(Roefa)

2,392 posts

·

Joined 2004

Roefa said:Hi Fish -

That's good advice from Joe and Bob. Keep your fingers away from those bits !

Also, if you have a lathe, that might be another way to make them. If you're not opposed to buying them, do a search on "Wood Toy Wheels" and you'll get lots of hits. Here's the first one I found:

http://www.craftparts.com/mall/page38.asp

..most any kind you can think of. Post some photos of your projects for us.

Good luck.

Roger

(Roefa)

Roger, those are sure good prices on little wheels! At those prices, why make them?! :sold:

4,126 posts

·

Joined 2006

I agree, great prices but then they are bags of 100, not sure how many would want 100 of them sitting around. Bookmarked that one!

Corey

Corey

23,784 posts

·

Joined 2006

Hi Corey

If it looks to good to be true it just maybe,,, the last time I ordered some off the net the price was about the same ,ONLY it was a each price.../10ea. in a bag,,, hardwood wheels for .06 cents ea.. hummmmmm sounds to to good.... see Rockler web page.

see Rockler web page.

I did send them a email just to check on it...

=======

# SW-1750

Price Per Bag of 12, $10.00,, bag of 48 $37.44

SW-1750 Spoke Wheels,,, 1-3/4" x 1/4" hole $10.00 per. 12

SW-2750 Spoke Wheels,,,2-3/4" x 3/8" hole $15.60 per. 12

==========

http://www.rockler.com/product.cfm?page=1538&filter=toy wheel

Great for old style model cars and wild west wagons.

Sets include axles and four wheels.

Spoked wheels come with tapered axle pegs,

sold in sets of 4.

http://www.rockler.com/product.cfm?page=1539

http://www.rockler.com/search_results.cfm?filter=toy+wheel&submit.x=21&submit.y=10

=============

If it looks to good to be true it just maybe,,, the last time I ordered some off the net the price was about the same ,ONLY it was a each price.../10ea. in a bag,,, hardwood wheels for .06 cents ea.. hummmmmm sounds to to good....

I did send them a email just to check on it...

=======

# SW-1750

Price Per Bag of 12, $10.00,, bag of 48 $37.44

SW-1750 Spoke Wheels,,, 1-3/4" x 1/4" hole $10.00 per. 12

SW-2750 Spoke Wheels,,,2-3/4" x 3/8" hole $15.60 per. 12

==========

http://www.rockler.com/product.cfm?page=1538&filter=toy wheel

Great for old style model cars and wild west wagons.

Sets include axles and four wheels.

Spoked wheels come with tapered axle pegs,

sold in sets of 4.

http://www.rockler.com/product.cfm?page=1539

http://www.rockler.com/search_results.cfm?filter=toy+wheel&submit.x=21&submit.y=10

=============

2,392 posts

·

Joined 2004

bobj3 said:Hi Corey

If it looks to good to be true it just maybe,,, the last time I ordered some off the net the price was about the same ,ONLY it was a each price.../10ea. in a bag,,, hardwood wheels for .06 cents ea.. hummmmmm sounds to to good....see Rockler web page.

I did send them a email just to check on it...

=======

# SW-1750

Price Per Bag of 12, $10.00,, bag of 48 $37.44

SW-1750 Spoke Wheels,,, 1-3/4" x 1/4" hole $10.00 per. 12

SW-2750 Spoke Wheels,,,2-3/4" x 3/8" hole $15.60 per. 12

=============

I think it's TRUE...

Their website Clearly states:

BEST BUY-10 or More Bags

Price per Bag of 100 Pieces

MW-1000 1" 1/4" 3/16" $5.50

Who is going to pay $5.50 for one 1" wheel?

http://www.craftparts.com/mall/page38.asp

This is really a super place to buy such items...

No doubt about it.

4,126 posts

·

Joined 2006

I think it is true as well, otherwise they would be in a little bit of trouble. If you add to the cart it will say the size/100. I wouldn't order them that way as I wouldn't want to be tripping over and storing bags of 100 wheels. They do sell a lot of the wheels in packs of 8, that makes more sense to me. Good link though to keep in the back pocket.

Corey

Corey

168 posts

·

Joined 2007

Well, one more option, gents...Fish, we'll git dis cat skint real good!!!

Try drilling the axle hole in your wood, then put a machine screw through

it with a couple of washers and a nut. Now chuck the screw in your drill press or

a strapped-down hand drill. Get files, sandpaper, whatever and go to it! Shape those wheels to however ya want 'em.

Roger

(Roefa)

Try drilling the axle hole in your wood, then put a machine screw through

it with a couple of washers and a nut. Now chuck the screw in your drill press or

a strapped-down hand drill. Get files, sandpaper, whatever and go to it! Shape those wheels to however ya want 'em.

Roger

(Roefa)

15,066 posts

·

Joined 2007

It isn't often that I agree with Joe, but I do agree with his method for the wheels, but make the "board " out of Acrylic so that you can see what's going on.

23,784 posts

·

Joined 2006

Hi Guys

Just one more way to make the SMALL Wheels

You can buy dowell rod and cut off all the wheels you need in a heart beat, with a bit of sanding you have them done..

With a stop block on the chop saw or the RAS you can make tons of them quick and easy..

1" one for about .01 ea. ,then make a quick jig for the drill press a drill the holes for the pins/dowel to hold them on the toy..

You can get dowel rod up to 2" dia..in hardwood the norm...

===========

Just one more way to make the SMALL Wheels

You can buy dowell rod and cut off all the wheels you need in a heart beat, with a bit of sanding you have them done..

With a stop block on the chop saw or the RAS you can make tons of them quick and easy..

1" one for about .01 ea. ,then make a quick jig for the drill press a drill the holes for the pins/dowel to hold them on the toy..

You can get dowel rod up to 2" dia..in hardwood the norm...

===========

439 posts

·

Joined 2007

Before you flame me and tell me how this is overkill --

Let me assure you - I would not disagree.

At those prices -- I would more than likely just buy the wheels.

And no -- I've never tried this.

Just sitting here bored and brainstorming.

But -- if I had a project that needed lots of wheels -

Or if I anticipated lots of projects requiring wheels --

and I decided I WANTED to make them and WANTED to use the router

-- this is probably what I would do --

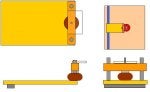

1)Make the base

Make a base/carrier out of 1/4" MDF or plywood

- Make it about 3" wide and about 2" longer than the distance from your miter track to your bit.

- cut two slots mounting screws

2)Make and attach a strip for the miter track

Cut a strip of wood about 3" long and the proper width and depth for your miter track.

Attach the strip to the base by running screws through the slots cut above.

This allows the base to be adjusted for different size wheels or different tables.

3)Cut and attach Dowels

-Put a 1/4" dowel about 3" long on each side to mount a 'hold-down' bar

-Put a 1/8" dowel about 3" long in the center to hold your wheel

4)Make a hold down strip out of 1/2" or 3/4" stock

- Make it as long as the narrow end of your base and about 3/4" wide

- Drill holes so that it will slide over the three dowels

If you have some scrap acrylic handy and want a little extra 'protection'

Cut a small shield and attach it to the hold-down bar.

5)Set up the cut

-Slide your wheel stock over the center pin followed by the washer.

-Then slide the hold-down bar in place

- Position your jig and set the depth of cut on your router for the desired roundover

- Tighten the screws holding the base to the miter strip

- Slide the jig back out of the way

6)Make the cut

-Turn your router on

-Hold the hold-down bar in place with the 4 fingers of one hand

-Hold the wheel stock with that thumb

-Use the other hand to slide the jig back into position

-As the stock comes in contact with the cutter -- slowly turn it with your thumb

Flip the wheel over and do the other side.

This assumes your wheel stock is CLOSE to round -- but since your distance is set by the center pin not the router bearing -- minor imperfections are taken care of.

You could adapt this same jig (without the plastic shield) to cut your initial circles.

If I knew I only planned on making one size wheel on one table --

I would probably skip the adjustment slots -- and just measure and mount the track strip as needed for this project.

Anyway -- just another way it CAN be done.

Let me assure you - I would not disagree.

At those prices -- I would more than likely just buy the wheels.

And no -- I've never tried this.

Just sitting here bored and brainstorming.

But -- if I had a project that needed lots of wheels -

Or if I anticipated lots of projects requiring wheels --

and I decided I WANTED to make them and WANTED to use the router

-- this is probably what I would do --

1)Make the base

Make a base/carrier out of 1/4" MDF or plywood

- Make it about 3" wide and about 2" longer than the distance from your miter track to your bit.

- cut two slots mounting screws

2)Make and attach a strip for the miter track

Cut a strip of wood about 3" long and the proper width and depth for your miter track.

Attach the strip to the base by running screws through the slots cut above.

This allows the base to be adjusted for different size wheels or different tables.

3)Cut and attach Dowels

-Put a 1/4" dowel about 3" long on each side to mount a 'hold-down' bar

-Put a 1/8" dowel about 3" long in the center to hold your wheel

4)Make a hold down strip out of 1/2" or 3/4" stock

- Make it as long as the narrow end of your base and about 3/4" wide

- Drill holes so that it will slide over the three dowels

If you have some scrap acrylic handy and want a little extra 'protection'

Cut a small shield and attach it to the hold-down bar.

5)Set up the cut

-Slide your wheel stock over the center pin followed by the washer.

-Then slide the hold-down bar in place

- Position your jig and set the depth of cut on your router for the desired roundover

- Tighten the screws holding the base to the miter strip

- Slide the jig back out of the way

6)Make the cut

-Turn your router on

-Hold the hold-down bar in place with the 4 fingers of one hand

-Hold the wheel stock with that thumb

-Use the other hand to slide the jig back into position

-As the stock comes in contact with the cutter -- slowly turn it with your thumb

Flip the wheel over and do the other side.

This assumes your wheel stock is CLOSE to round -- but since your distance is set by the center pin not the router bearing -- minor imperfections are taken care of.

You could adapt this same jig (without the plastic shield) to cut your initial circles.

If I knew I only planned on making one size wheel on one table --

I would probably skip the adjustment slots -- and just measure and mount the track strip as needed for this project.

Anyway -- just another way it CAN be done.

Attachments

-

21 KB Views: 252

2,392 posts

·

Joined 2004

The only thing that I don't care for, using Dowels, is all of the Wheels would have cross-grain on the main surfaces of the wheels which would make it harder to finish and would also be very weak and easier to break.bobj3 said:Hi Guys

Just one more way to make the SMALL Wheels

You can buy dowell rod and cut off all the wheels you need in a heart beat, with a bit of sanding you have them done..

With a stop block on the chop saw or the RAS you can make tons of them quick and easy..

1" one for about .01 ea. ,then make a quick jig for the drill press a drill the holes for the pins/dowel to hold them on the toy..

You can get dowel rod up to 2" dia..in hardwood the norm...

===========

2,392 posts

·

Joined 2004

Now, there's a real system for making small wheels!Drugstore Cowboy said:Before you flame me and tell me how this is overkill --

Let me assure you - I would not disagree.

At those prices -- I would more than likely just buy the wheels.

And no -- I've never tried this.

Just sitting here bored and brainstorming.

But -- if I had a project that needed lots of wheels -

Or if I anticipated lots of projects requiring wheels --

and I decided I WANTED to make them and WANTED to use the router

-- this is probably what I would do --

1)Make the base

Make a base/carrier out of 1/4" MDF or plywood

- Make it about 3" wide and about 2" longer than the distance from your miter track to your bit.

- cut two slots mounting screws

2)Make and attach a strip for the miter track

Cut a strip of wood about 3" long and the proper width and depth for your miter track.

Attach the strip to the base by running screws through the slots cut above.

This allows the base to be adjusted for different size wheels or different tables.

3)Cut and attach Dowels

-Put a 1/4" dowel about 3" long on each side to mount a 'hold-down' bar

-Put a 1/8" dowel about 3" long in the center to hold your wheel

4)Make a hold down strip out of 1/2" or 3/4" stock

- Make it as long as the narrow end of your base and about 3/4" wide

- Drill holes so that it will slide over the three dowels

If you have some scrap acrylic handy and want a little extra 'protection'

Cut a small shield and attach it to the hold-down bar.

5)Set up the cut

-Slide your wheel stock over the center pin followed by the washer.

-Then slide the hold-down bar in place

- Position your jig and set the depth of cut on your router for the desired roundover

- Tighten the screws holding the base to the miter strip

- Slide the jig back out of the way

6)Make the cut

-Turn your router on

-Hold the hold-down bar in place with the 4 fingers of one hand

-Hold the wheel stock with that thumb

-Use the other hand to slide the jig back into position

-As the stock comes in contact with the cutter -- slowly turn it with your thumb

Flip the wheel over and do the other side.

This assumes your wheel stock is CLOSE to round -- but since your distance is set by the center pin not the router bearing -- minor imperfections are taken care of.

You could adapt this same jig (without the plastic shield) to cut your initial circles.

If I knew I only planned on making one size wheel on one table --

I would probably skip the adjustment slots -- and just measure and mount the track strip as needed for this project.

Anyway -- just another way it CAN be done.

439 posts

·

Joined 2007

Thanks - it made sense to meJoe Lyddon said:Now, there's a real system for making small wheels!

:sold:

ACTUALLY --

I DID catch one detail that I am sure others have as well.

If you were going to do something similar to this -

You will want TWO fingers on the wheel stock.

One to rotate it --

The other to hold it steady - keep the router bit from spinning it when you reposition your 'rotating' finger.

23,784 posts

·

Joined 2006

Hi Cowboy

I surprise you didn't say HOLE SAW/Rosette bit, that's quite a jig do do just a simple thing like make toys wheels that jig would be just a bit hairy for the 1" ones...and smaller...

that jig would be just a bit hairy for the 1" ones...and smaller...

But you know I like jigs so a I say hurrah for one more way to make them good job Cowboy

..

============

I surprise you didn't say HOLE SAW/Rosette bit, that's quite a jig do do just a simple thing like make toys wheels

But you know I like jigs so a I say hurrah for one more way to make them good job Cowboy

..

============

Drugstore Cowboy said:Before you flame me and tell me how this is overkill --

Let me assure you - I would not disagree.

At those prices -- I would more than likely just buy the wheels.

And no -- I've never tried this.

Just sitting here bored and brainstorming.

But -- if I had a project that needed lots of wheels -

Or if I anticipated lots of projects requiring wheels --

and I decided I WANTED to make them and WANTED to use the router

-- this is probably what I would do --

1)Make the base

Make a base/carrier out of 1/4" MDF or plywood

- Make it about 3" wide and about 2" longer than the distance from your miter track to your bit.

- cut two slots mounting screws

2)Make and attach a strip for the miter track

Cut a strip of wood about 3" long and the proper width and depth for your miter track.

Attach the strip to the base by running screws through the slots cut above.

This allows the base to be adjusted for different size wheels or different tables.

3)Cut and attach Dowels

-Put a 1/4" dowel about 3" long on each side to mount a 'hold-down' bar

-Put a 1/8" dowel about 3" long in the center to hold your wheel

4)Make a hold down strip out of 1/2" or 3/4" stock

- Make it as long as the narrow end of your base and about 3/4" wide

- Drill holes so that it will slide over the three dowels

If you have some scrap acrylic handy and want a little extra 'protection'

Cut a small shield and attach it to the hold-down bar.

5)Set up the cut

-Slide your wheel stock over the center pin followed by the washer.

-Then slide the hold-down bar in place

- Position your jig and set the depth of cut on your router for the desired roundover

- Tighten the screws holding the base to the miter strip

- Slide the jig back out of the way

6)Make the cut

-Turn your router on

-Hold the hold-down bar in place with the 4 fingers of one hand

-Hold the wheel stock with that thumb

-Use the other hand to slide the jig back into position

-As the stock comes in contact with the cutter -- slowly turn it with your thumb

Flip the wheel over and do the other side.

This assumes your wheel stock is CLOSE to round -- but since your distance is set by the center pin not the router bearing -- minor imperfections are taken care of.

You could adapt this same jig (without the plastic shield) to cut your initial circles.

If I knew I only planned on making one size wheel on one table --

I would probably skip the adjustment slots -- and just measure and mount the track strip as needed for this project.

Anyway -- just another way it CAN be done.

439 posts

·

Joined 2007

Well -bobj3 said:Hi Cowboy

I surprise you didn't say HOLE SAW/Rosette bit, that's quite a jig do do just a simple thing like make toys wheelsthat jig would be just a bit hairy for the 1" ones...and smaller...

But you know I like jigs so a I say hurrah for one more way to make them good job Cowboy

..

============

- that it would likely be more trouble than it is worth -

- I acknowledged in my first two sentences.

The only reasons I can think of to do it this way -

- would be if you wanted to do it on the router table -

- and if you just enjoyed tinkering with jigs.

Oh - And that it gives you one jig you can use for both cutting the original circles - and doing the roundovers.

As for why I didn't suggest a rosette cutter --

That's easy -

I don't have one

And I do have the scraps needed to make the jig.

I was brainstorming is what I would do.

And my first inclination is always to use what I have on hand before going to buy something.

As for it being 'hairy' for a 1" wheel -- I'm at a loss there -

As I sketched out the plans -- I scaled it around a 1" wheel.

See no reason it wouldn't work.

Yes -- if you got much smaller than 1" -- you would need to adapt

And frankly -- I probably wouldn't bother -- just buy 'em.

If by hairy you mean scarey -- I don't see it the problem.

Anyway -- not arguing -- just replying.

Like I said -- I've never actually done this.

Chances are if I ever do -- I may not like it

You never know.

I've made myself curious now though --

Have no need for wheels -- but may have to throw this together this weekend and test it out.

Thanks for the kind words.

23,784 posts

·

Joined 2006

Hi Cowboy

Toys are great to make, and give them away to the kids at Xmax...If I recall Doug ask the members to make some and he would get them to the kids this year but it's bit late now but it would be great if you and others would make some for next year they are fun to make with the scrap stock we all have in the shop,,,,I did make some this year but they are going to the grandkids this year but maybe next year

but it would be great if you and others would make some for next year they are fun to make with the scrap stock we all have in the shop,,,,I did make some this year but they are going to the grandkids this year but maybe next year

"rosette cutter" ,,,no jig needed just a drill press and some scrap wood, clamp the stock down cut one side then flip it over and do the other side to make a great toy wheels...

http://www.grizzly.com/products/searchresults.aspx?q=rosette+&submit.x=7&submit.y=9

http://www.grizzly.com/products/searchresults.aspx?q=rosette+cutter&submit.x=8&submit.y=9

==============

Toys are great to make, and give them away to the kids at Xmax...If I recall Doug ask the members to make some and he would get them to the kids this year but it's bit late now

"rosette cutter" ,,,no jig needed just a drill press and some scrap wood, clamp the stock down cut one side then flip it over and do the other side to make a great toy wheels...

http://www.grizzly.com/products/searchresults.aspx?q=rosette+&submit.x=7&submit.y=9

http://www.grizzly.com/products/searchresults.aspx?q=rosette+cutter&submit.x=8&submit.y=9

==============

Drugstore Cowboy said:Well -

- that it would likely be more trouble than it is worth -

- I acknowledged in my first two sentences.

The only reasons I can think of to do it this way -- would be if you wanted to do it on the router table -- and if you just enjoyed tinkering with jigs.

As for why I didn't suggest a rosette cutter --

That's easy -

I don't have one

And I do have the scraps needed to make the jig.

I was brainstorming is what I would do.

And my first inclination is always to use what I have on hand before going to buy something.

As for it being 'hairy' for a 1" wheel -- I'm at a loss there -

As I sketched out the plans -- I scaled it around a 1" wheel.

See no reason it wouldn't work.

Yes -- if you got much smaller than 1" -- you would need to adapt

And frankly -- I probably wouldn't bother -- just buy 'em.

If by hairy you mean scarey -- I don't see it the problem.

Anyway -- not arguing -- just replying.

Like I said -- I've never actually done this.

Chances are if I ever do -- I may not like it

You never know.

Thanks for the kind words.

439 posts

·

Joined 2007

BJ -

I couldn't agree more on the rosette cutter idea.:sold:

It takes care of both the rounding over for the 'tire' and the shaping of the 'wheel'. It's a great idea --

IF you have one and a drill press to mount it in

Since I don't --

I have to stand by any of the other ideas that were mentioned as being less expensive/easier - up front.

As for my specific suggestion---

I was trying to address fishlore's original queston ---

"I've got a 1/4" round-over bit with a bearing mounted in the router but I'm uneasy about getting my fingers all that close to the bit. Is there a good technique for holding these small pieces?" (emphasis added)

That was what was asked -- so that is what my bored brain set about trying to answer nothing more --

nothing more --

As for a drill press ----

I'm hoping maybe Santy Claus will bring me one for Christmas --

If he does -- I promise to make some toys for charity next year.

I've been looking for a good excuse to do some of that.

Unfortunately -- all the kids in my family are a bit past that stage.:'(

I couldn't agree more on the rosette cutter idea.:sold:

It takes care of both the rounding over for the 'tire' and the shaping of the 'wheel'. It's a great idea --

IF you have one and a drill press to mount it in

Since I don't --

I have to stand by any of the other ideas that were mentioned as being less expensive/easier - up front.

As for my specific suggestion---

I was trying to address fishlore's original queston ---

"I've got a 1/4" round-over bit with a bearing mounted in the router but I'm uneasy about getting my fingers all that close to the bit. Is there a good technique for holding these small pieces?" (emphasis added)

That was what was asked -- so that is what my bored brain set about trying to answer

As for a drill press ----

I'm hoping maybe Santy Claus will bring me one for Christmas --

If he does -- I promise to make some toys for charity next year.

I've been looking for a good excuse to do some of that.

Unfortunately -- all the kids in my family are a bit past that stage.:'(

23,784 posts

·

Joined 2006

Hi Cowboy

You don't need a drill press to use them (rosette cutters) I have seen some use them in a good 1/2" drill motor, the hard part in using them with the hand drill is starting them because most don't have a center pin to keep them running true...but it can be done..once they dig in just a bit you can hold it true...the last time I saw someone use them without a drill press he had blocks on the side of the bit to keep it running true, but it takes a drill like a hole hog to turn them..they are removing tons of stock in one turn of the bit.....

Doing it on the router table,, like I said in the 1st part of this post not a good way to do this job...fingers are hard to glue back on and it's only a wood toy wheel...

I don't like to get my fingers or my hand with it 6" of the bit that running at 10,000 rpm's or more ,,,no jig in the world can replace my parts if they get removed by taking a chance with a router bit..just takes a sec.and it's gone...plus I don't like the red color on my router table to remind me how dumb I was in trying that in the 1st. place....

==============

You don't need a drill press to use them (rosette cutters) I have seen some use them in a good 1/2" drill motor, the hard part in using them with the hand drill is starting them because most don't have a center pin to keep them running true...but it can be done..once they dig in just a bit you can hold it true...the last time I saw someone use them without a drill press he had blocks on the side of the bit to keep it running true, but it takes a drill like a hole hog to turn them..they are removing tons of stock in one turn of the bit.....

Doing it on the router table,, like I said in the 1st part of this post not a good way to do this job...fingers are hard to glue back on and it's only a wood toy wheel...

I don't like to get my fingers or my hand with it 6" of the bit that running at 10,000 rpm's or more ,,,no jig in the world can replace my parts if they get removed by taking a chance with a router bit..just takes a sec.and it's gone...plus I don't like the red color on my router table to remind me how dumb I was in trying that in the 1st. place....

==============

439 posts

·

Joined 2007

That's your opinion - and you are certainly welcome to it.bobj3 said:Hi Cowboy

. . .

Doing it on the router table,, like I said in the 1st part of this post not a good way to do this job...fingers are hard to glue back on and it's only a wood toy wheel...

I don't like to get my fingers or my hand with it 6" of the bit that running at 10,000 rpm's or more ,,,

==============

I totally agree with the need to respect any tool that can do that much damage.

Frankly -- as concerned as you are about doing this on a router --

I would be that concerned trying to use a rosette cutter in a hand held drill.

My wrists are just not that steady.

As to whether using the router is a good tool to use for this or not -

I wouldn't argue one way or the other --- never tried it.

Again that wasn't the question I was answering --

I was answering the question - is there a way to hold small pieces so they could be rounded over with a router.

I've looked and looked back at my design -- and I dont see any reasonable way of getting your fingers and the bit together.

Right now though -- its just a idea on paper --

I'll have to make a prototype and see.

If I am typing my posts with fewer fingers after the holidays --

I guess you were right.

For now -- I think this tangent of the discussion has gone as far as it needs to. It all boils down to personal preference -- and there is no right or wrong.

Besides- -- Happy Hour starts in 5 minutes !!!

23,784 posts

·

Joined 2006

Hi Cowboy

hahahahaahahahahahahahaha I'm trying to goat you into trying it hahahahahahaha.

Like Bob R. will say all the time get your router out and have some fun with it...and making some toys ,it's a great way to do that..

But you will need for go the happy hour.. LOL LOL

I'm looking forward to seeing your jig and wheels that you have made with it for the toys next year I hope .. I'm sure you must have some scrap wood in the shop.

I'm sure you must have some scrap wood in the shop.

===========

hahahahaahahahahahahahaha I'm trying to goat you into trying it hahahahahahaha.

Like Bob R. will say all the time get your router out and have some fun with it...and making some toys ,it's a great way to do that..

But you will need for go the happy hour.. LOL LOL

I'm looking forward to seeing your jig and wheels that you have made with it for the toys next year I hope ..

===========

439 posts

·

Joined 2007

If you mean -- using a rosette cutter in a hand held drill ----bobj3 said:Hi Cowboy

hahahahaahahahahahahahaha I'm trying to goat you into trying it hahahahahahaha.

===========

NOT gonna happen

I ran a 1" spade bit through some sheetrock once -- and hit some 90 year old Southern Yellow Pine ---

That taught this old dawg all he needs to know about torque and leverage.

NOT denying that others may be able to do it -- but I know my limitations.

I'll let that wait on the drill press.

Don't doubt it for a second --I've always wanted to explore toy making.bobj3 said:Like Bob R. will say all the time get your router out and have some fun with it...and making some toys ,it's a great way to do that..

===========

But first I have to learn to quit letting myself get talked into these remodelign type projects.

Between now an New Years I have a floor to refinish -- garage doors to replace and a pergola to build -- MOST of which are in the nature of favors -

ie -- I will do good to break even on materials

Count on it --bobj3 said:I'm looking forward to seeing your jig and wheels that you have made with it for the toys next year I hope ..I'm sure you must have some scrap wood in the shop.

===========

Originally that design was just a hypothetical answer to fishlore's question.

But now I've gotten myself curious --

Gonna HAVE to try it.

And I will let you see the results -- good or bad.

===========[/QUOTE]

23,784 posts

·

Joined 2006

HI Cowboy

That's it get ticked off and say I will show you smart A@*,,,, that's what I had in mine... it's alway best to try something new, that's the fun thing about the router...it can do so much and I'm sure you will come up with a neat way to do it..

it's alway best to try something new, that's the fun thing about the router...it can do so much and I'm sure you will come up with a neat way to do it..

I just need to get you to try it but pls. be care-full don't remove any parts you will need down the road...

but pls. be care-full don't remove any parts you will need down the road...

===========

That's it get ticked off and say I will show you smart A@*,,,, that's what I had in mine...

I just need to get you to try it

===========

666 posts

·

Joined 2004

There is only one way to convince others that what you have submitted as a solution is correct, is to try it first before posting. I could have said maybe it could have been produced with the use of template guides. Before a couple go shouting at me I said Maybe it could have been done. The only way to prove it is to try it and maybe by the end of the week I will have given it a go.

I must say they are very small. In the past I have produced 50mm (2") wheels with the aid of the guides.

As Bob says it is the fun trying it and it makes you feel good if it works.

So if you think you have a solution try it out first, personally I would not be in favour of using the router with the methods presented in the earlier posts.

I for one would be interested in the attempts of others.

Tom

I must say they are very small. In the past I have produced 50mm (2") wheels with the aid of the guides.

As Bob says it is the fun trying it and it makes you feel good if it works.

So if you think you have a solution try it out first, personally I would not be in favour of using the router with the methods presented in the earlier posts.

I for one would be interested in the attempts of others.

Tom

- Status

- Not open for further replies.

You have insufficient privileges to reply here.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 760K

- members

- 137K

- Since

- 2004

A forum community dedicated to router and woodworking professionals and enthusiasts. Come join the discussion about different types of routing and routers, shop safety, finishing, woodworking related topics, styles, tools, scales, reviews, accessories, classifieds, and more!

Top Contributors this Month

View All

DesertRatTom

166 Replies

old55

90 Replies

BladesNBarrels

62 Replies