Has anyone tried steam bending hardwoods for any of their projects? How difficult was the process of steam bending the wood for your project?

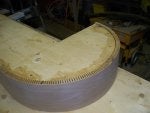

You see kits from Rockler and several other vendors showing people steam bending wood. Some of the videos make steam bending look relatively like a straight forward process. I would think it would really depend on the type of hardwood you’re trying to bend.

Like everything on the internet, you never really know how hard it will be until you try yourself.

You see kits from Rockler and several other vendors showing people steam bending wood. Some of the videos make steam bending look relatively like a straight forward process. I would think it would really depend on the type of hardwood you’re trying to bend.

Like everything on the internet, you never really know how hard it will be until you try yourself.