The table saw is the most used tool you're going have in your arsenal, but lets face it, good table saws are super expensive and big and heavy and even at best the fence is still well... sub-standard on most of them, forcing yet another expensive purchase to get the accuracy and precision you want and expect from a table saw fence.

Please note this tablesaw has its limits and is not built to play with the big saws but it can deliver incredible accuracy you would get from a highend tablesaw. For most projects like picture frames kitchen cabinet doors and whatever you want to throw at it that will fit on the table.. its game.

So are there any other options for someone that has a small workshop or a small budget? Is the $5000 dream saw out of reach? Well there's something here that might tickle your fancy or just make you say ya right or make you go duh!! The table Saw here is the Ridgid TS4516 10" portable contractor's saw you can find at Home Depot on sale for a whooping $249.00. Hey!! even the 36T rip blade that comes with it is fairly good, but these portable table saws have their limits and it's the power of motor and the size of the table, but for most smaller projects it's more than adequate if you spend the time to give it a tune up, or in this case an overhaul with some Incra goodies to trick it out.

to trick it out.

Ok. On to the good stuff... I started off by squaring up the blade and the fence. It was an easy task with the adjustments on the rear of the chassis. After that I checked the arbor runout with dial indicator. Great news, it hardly moved the needle as I turned the arbor full rotatations. This shows that Ridgid put some quality into the design.

With this out of the way, it was time to give this little saw a home inside of a 36 X 24 X 3/4 euro cabinet I found at the local Ikea scratch and dent section for a meager $29. I added wheels and levelers and a 60 X 30 X 1 1/8" high pressure melamine top I cut to fit around the saw table. I fastened down the top using a pocket hole jig and screws, making this top rock solid to the cabinet. Plus, for good measure, I added extra pocket holes and screws at the base making it even stronger.

The cutoffs left from the top were added to stiffen the base cabinet to prevent twist while moving it around. The work bench behind the saw is set at the same height so it can double as an outfeed table for longer cuts. The Ridgid 36T blade was replaced with the Freud Thin Kerf 60T Ultra fine finish crosscut blade, (NOTE: I recommend the use of 3 1/2 blade stiffeners with a kerf under 1/8 to minimize blade flutter and vibration and of course, blade noise.) Yes, they're worth every penny if you really care about precision like I do.

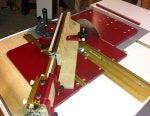

So what makes this saw so accurate down to 0.001? It's the Incra 25" LS Positioner and fence I adapted from my Incra router table system. I just wanted to see if this would work as good as it does on my router table. Oh hell ya!! Even at a full 25" cross cut it's spot on everytime! No matter where you set it. It's very easy to square up to the blade. Just pull the fence to the blade and pull the LS Positioner clamp up half way and use the micro adjuster to dial it in perfect and then lock the LS Positioner clamp all the way and run a test cut. Measure your cut with a digital caliper because this will help you fine tune the fence to perfection. Once you find the sweet spot, slide the magnetic rule strip on the positioner's carriage to read 0 on the curser line in the window on the LS base and forget about ever using a tape measure again. "The measure tap cut and scrap method" that is so frustrating will never plague you again!

DO I HAVE YOUR ATTENTION YET? OK, SO WHAT WILL THIS COST YOU?

The Incra LS 25" will run you about $299 for the package or you can buy the LS Positioner on it's own for $200 and add your own fence, or you can get their fence systems for most table saws made today. (more info at Dovetails & Precision Woodworking with Incra Fences, Jigs, Rules and Other Precise Woodworking Tools. They also have some cool live demos.) So there you have it! The little Ridgid saw that has machine shop quality cuts you only dream about for the cost of $750 including the blade,

(PLEASE NOTE: I did not in any way modify or re-engineer the table saw itself and I don't recommend doing so for safety reasons. I just made it work better.) Here are some pictures of this setup. By the way, I decided this setup deserves a nice set of birch cabinet doors for the storage area below. I also added the Incra Miter Express with the 1000SE miter gauge, this is one deadly accurate combo for any table saw.

Cheers

Glen

Please note this tablesaw has its limits and is not built to play with the big saws but it can deliver incredible accuracy you would get from a highend tablesaw. For most projects like picture frames kitchen cabinet doors and whatever you want to throw at it that will fit on the table.. its game.

So are there any other options for someone that has a small workshop or a small budget? Is the $5000 dream saw out of reach? Well there's something here that might tickle your fancy or just make you say ya right or make you go duh!! The table Saw here is the Ridgid TS4516 10" portable contractor's saw you can find at Home Depot on sale for a whooping $249.00. Hey!! even the 36T rip blade that comes with it is fairly good, but these portable table saws have their limits and it's the power of motor and the size of the table, but for most smaller projects it's more than adequate if you spend the time to give it a tune up, or in this case an overhaul with some Incra goodies

Ok. On to the good stuff... I started off by squaring up the blade and the fence. It was an easy task with the adjustments on the rear of the chassis. After that I checked the arbor runout with dial indicator. Great news, it hardly moved the needle as I turned the arbor full rotatations. This shows that Ridgid put some quality into the design.

With this out of the way, it was time to give this little saw a home inside of a 36 X 24 X 3/4 euro cabinet I found at the local Ikea scratch and dent section for a meager $29. I added wheels and levelers and a 60 X 30 X 1 1/8" high pressure melamine top I cut to fit around the saw table. I fastened down the top using a pocket hole jig and screws, making this top rock solid to the cabinet. Plus, for good measure, I added extra pocket holes and screws at the base making it even stronger.

The cutoffs left from the top were added to stiffen the base cabinet to prevent twist while moving it around. The work bench behind the saw is set at the same height so it can double as an outfeed table for longer cuts. The Ridgid 36T blade was replaced with the Freud Thin Kerf 60T Ultra fine finish crosscut blade, (NOTE: I recommend the use of 3 1/2 blade stiffeners with a kerf under 1/8 to minimize blade flutter and vibration and of course, blade noise.) Yes, they're worth every penny if you really care about precision like I do.

So what makes this saw so accurate down to 0.001? It's the Incra 25" LS Positioner and fence I adapted from my Incra router table system. I just wanted to see if this would work as good as it does on my router table. Oh hell ya!! Even at a full 25" cross cut it's spot on everytime! No matter where you set it. It's very easy to square up to the blade. Just pull the fence to the blade and pull the LS Positioner clamp up half way and use the micro adjuster to dial it in perfect and then lock the LS Positioner clamp all the way and run a test cut. Measure your cut with a digital caliper because this will help you fine tune the fence to perfection. Once you find the sweet spot, slide the magnetic rule strip on the positioner's carriage to read 0 on the curser line in the window on the LS base and forget about ever using a tape measure again. "The measure tap cut and scrap method" that is so frustrating will never plague you again!

DO I HAVE YOUR ATTENTION YET? OK, SO WHAT WILL THIS COST YOU?

The Incra LS 25" will run you about $299 for the package or you can buy the LS Positioner on it's own for $200 and add your own fence, or you can get their fence systems for most table saws made today. (more info at Dovetails & Precision Woodworking with Incra Fences, Jigs, Rules and Other Precise Woodworking Tools. They also have some cool live demos.) So there you have it! The little Ridgid saw that has machine shop quality cuts you only dream about for the cost of $750 including the blade,

(PLEASE NOTE: I did not in any way modify or re-engineer the table saw itself and I don't recommend doing so for safety reasons. I just made it work better.) Here are some pictures of this setup. By the way, I decided this setup deserves a nice set of birch cabinet doors for the storage area below. I also added the Incra Miter Express with the 1000SE miter gauge, this is one deadly accurate combo for any table saw.

Cheers

Glen