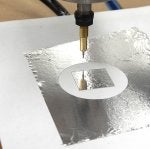

I setup the new drag knife from donektools.com ,its 1/2 shank goes in the router

collet or spindle takes standard box knife blades this model the D2 will cut up to

1/4 materials.

Programmed the cut using aspire

and calling it a 1/64 end mill and ramping it in 1 inch for the cut

You can contact Sean Martin (smartin@donek.com) for more info or me

I am anxious to try more materials like vinyl or veneers or a heavier plastic

using donektools drag knife on thin plastic ,trial runs - YouTube

collet or spindle takes standard box knife blades this model the D2 will cut up to

1/4 materials.

Programmed the cut using aspire

and calling it a 1/64 end mill and ramping it in 1 inch for the cut

You can contact Sean Martin (smartin@donek.com) for more info or me

I am anxious to try more materials like vinyl or veneers or a heavier plastic

using donektools drag knife on thin plastic ,trial runs - YouTube