Hi Guys I'm new to the forum and live in Australia

At the moment I'm making a few knick knacks (jewellery) in between making guitars.

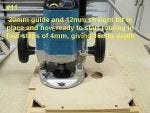

The main thing I am struggling with is cutting small circles (between 1.5 and 2 inches in Diameter (30-40mm)). I don't really want to use plug cutters as I'm sure there is a way to do it with the tools I have (small bandsaw, router, drill press, laminate trimmer)

The circles would be easy to cut if I wanted a centre hole, but I want there to be no centre hole. I don't mind if there is a pin hole on the back side as I can fill that with epoxy/ filler. I'm mainly using highly figured curly timbers (scraps) and when I tried out the jig pictured below, the wood just split down the curly/ fiddle back grain lines (leaving 3/4 of a circle.)

![Image]()

![Image]()

![Image]()

The stock I'm using is about 2-4 mm thick

I was also wondering if a similar jig would work better on a scroll saw (the blade might be a bit close to the clamp though...)?

Other alternatives. I could just program the circle into Cad and get them Laser cut. that would cost about 100 bucks for a few hundred circles.

At the moment I'm making a few knick knacks (jewellery) in between making guitars.

The main thing I am struggling with is cutting small circles (between 1.5 and 2 inches in Diameter (30-40mm)). I don't really want to use plug cutters as I'm sure there is a way to do it with the tools I have (small bandsaw, router, drill press, laminate trimmer)

The circles would be easy to cut if I wanted a centre hole, but I want there to be no centre hole. I don't mind if there is a pin hole on the back side as I can fill that with epoxy/ filler. I'm mainly using highly figured curly timbers (scraps) and when I tried out the jig pictured below, the wood just split down the curly/ fiddle back grain lines (leaving 3/4 of a circle.)

The stock I'm using is about 2-4 mm thick

I was also wondering if a similar jig would work better on a scroll saw (the blade might be a bit close to the clamp though...)?

Other alternatives. I could just program the circle into Cad and get them Laser cut. that would cost about 100 bucks for a few hundred circles.