Guys I am going to replace my table saws extention with my Incra router table . (I am also building a separate Incra RT at a later date )

For strength I want to reinforce the incra table with a torsion box . I watched a video and he has nailed individual pieces inside . Wouldn't it be better to dado all the cross pieces so they interlocked . Kibosh the air nails and use lots of weld bond glue ?

I wasn't going to add a bottom to the torsion box as I was going to glue the pieces to the incra tables bottom so you can see the grid pattern underneath .

I guess I could add a bottom for strength if it's necessary , as there will be a large hole for the router lift to stick threw .

I will need access underneath the sides for bolt holes where the box will be attached to the table saws fence . Although I could route openings for that too .

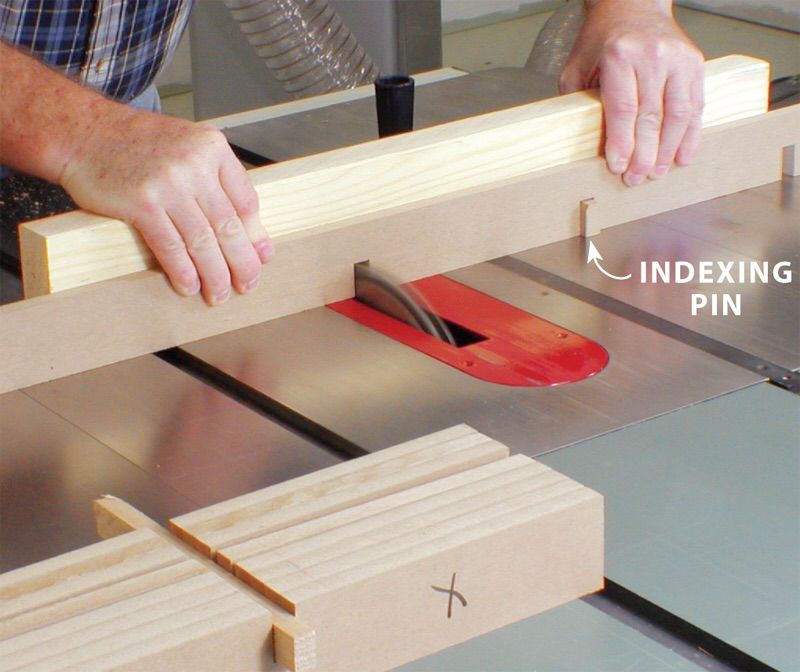

Here's a video I watched , but it's not the way I really want to go about it

Build a Torsion Box Assembly Table - Fine Woodworking Video

For strength I want to reinforce the incra table with a torsion box . I watched a video and he has nailed individual pieces inside . Wouldn't it be better to dado all the cross pieces so they interlocked . Kibosh the air nails and use lots of weld bond glue ?

I wasn't going to add a bottom to the torsion box as I was going to glue the pieces to the incra tables bottom so you can see the grid pattern underneath .

I guess I could add a bottom for strength if it's necessary , as there will be a large hole for the router lift to stick threw .

I will need access underneath the sides for bolt holes where the box will be attached to the table saws fence . Although I could route openings for that too .

Here's a video I watched , but it's not the way I really want to go about it

Build a Torsion Box Assembly Table - Fine Woodworking Video