Okay.

As many of you know, I am totally clueless and new to woodworking.

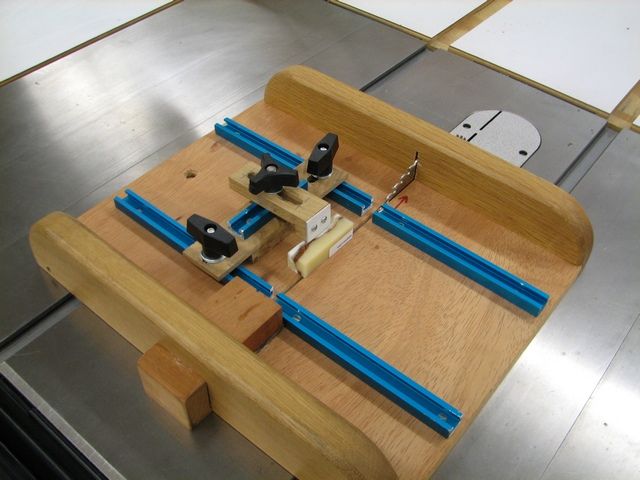

I am planning to build a Crosscut Sled for my Kobalt Contractors table saw.

Crosscut saws are almost as unique as fingerprints, there are so many variations out there.

Runners are my major speed bump.

I just can't justify spending $50 for Incra steel runners.

But beyond "use hardwood," everything gets iffy and cloudy.

I saw a YT video, where someone used a piece of cocobolo wood flooring they got from a hardwood flooring dumpster (possible wood source?), and that got me thinking...

could I use a length of hardwood flooring to make my runners???

Here is the list of what my nearest floor shop offers:

http://columber.net/hws2s.html

It's 3/4 thickness, 2 1/4"-5" widths, sold by the square foot...

Which wood would be best to get?

Is Purple heart worth the expense?

The price beats the $8-$10/sq. ft price from the Orange Box store...

And the selection of hardwoods is better. Like I need more confusion of choice...

~M

As many of you know, I am totally clueless and new to woodworking.

I am planning to build a Crosscut Sled for my Kobalt Contractors table saw.

Crosscut saws are almost as unique as fingerprints, there are so many variations out there.

Runners are my major speed bump.

I just can't justify spending $50 for Incra steel runners.

But beyond "use hardwood," everything gets iffy and cloudy.

I saw a YT video, where someone used a piece of cocobolo wood flooring they got from a hardwood flooring dumpster (possible wood source?), and that got me thinking...

could I use a length of hardwood flooring to make my runners???

Here is the list of what my nearest floor shop offers:

http://columber.net/hws2s.html

It's 3/4 thickness, 2 1/4"-5" widths, sold by the square foot...

Which wood would be best to get?

Is Purple heart worth the expense?

The price beats the $8-$10/sq. ft price from the Orange Box store...

And the selection of hardwoods is better. Like I need more confusion of choice...

~M