Guys I think I'm going to kibosh using my Incra router table top for my table saws extention and build it from scratch .

At the prices of material I won't be saving money but building the top and fence from scratch will be a great learning experience and it will fit my table saw better and look cleaner .

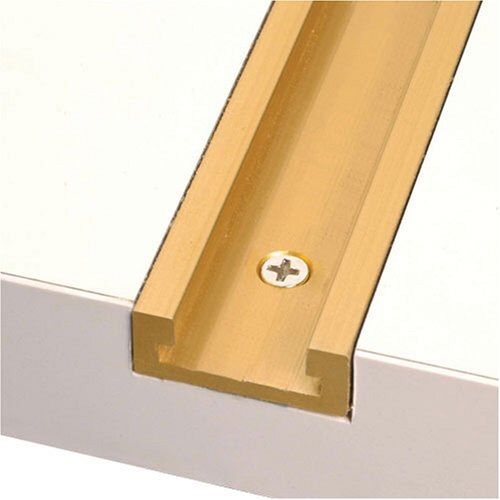

Which would be the best way to secure the fence down as I see people typically route or dado a channel in the table top and use some kinda of aluminum channel . I also need to source something for a miter slot and channel for the fence to hold feather boards .

Would this be overkill going with this Kregs work table channel to secure the fence?

http://www.amazon.ca/Kreg-KKS1020-K...ak/dp/B000SRI4JE/ref=sr_1_33?ie=UTF8&qid=1431804232&sr=8-33&keywords=kreg+tools

At the prices of material I won't be saving money but building the top and fence from scratch will be a great learning experience and it will fit my table saw better and look cleaner .

Which would be the best way to secure the fence down as I see people typically route or dado a channel in the table top and use some kinda of aluminum channel . I also need to source something for a miter slot and channel for the fence to hold feather boards .

Would this be overkill going with this Kregs work table channel to secure the fence?

http://www.amazon.ca/Kreg-KKS1020-K...ak/dp/B000SRI4JE/ref=sr_1_33?ie=UTF8&qid=1431804232&sr=8-33&keywords=kreg+tools