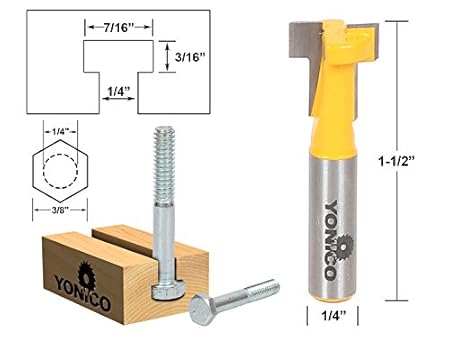

Found a cool bit on-line tonight. It's a slot cutter that conforms to a standard 1/4 20 Bolt head, wish I could find one with a 1/2" shank though. I tried to do this with a Rockler T-Slot bit, but it cuts a 5/8" wide slot that lets the head of a 1/4 20 hex bolt (7/16" head - 1/2" point to point) rotate in the track.

![Image]()

So why should you care? Bolts designed to work in extruded T Track (or various T-slot cutter bits) are often near $1.00 US, EACH! I can get a box of 100 1/4 20 2" bolts for less than $15. To me this brings low cost, adjustable, fixturing to a new level. The bolts also work very well in Incra extruded aluminum T-tracks.

So why should you care? Bolts designed to work in extruded T Track (or various T-slot cutter bits) are often near $1.00 US, EACH! I can get a box of 100 1/4 20 2" bolts for less than $15. To me this brings low cost, adjustable, fixturing to a new level. The bolts also work very well in Incra extruded aluminum T-tracks.