Don't want to burst bubbles just caution you.

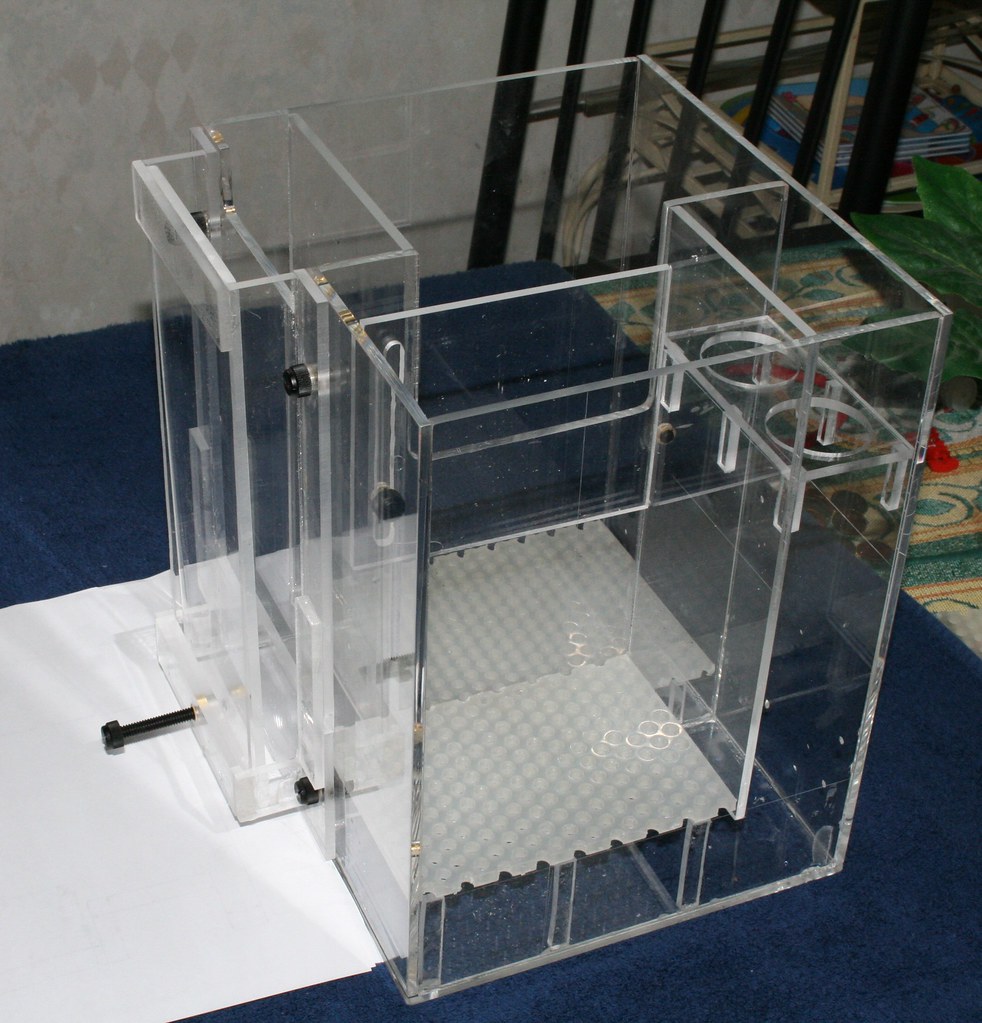

I work plastic, mostly acrylic, some PVC, PC et.al.

A bandsaw, drill, grind/sand, and rout the material.

Drilling is rife with adversity. The work can shatter, climb up the drill or melt in your face. The bandsaw is very forgiving but it has its caveats.

And routing is altogther like nothing else; usually done at 20krpm+ and always with carbide.

All operations require your attention with respect to holding the work accurately and in total isolation. A work piece has 12 degrees of freedom; the fixturing that holds the work also has its immobilization issues.

Bottomline: Consider your local resources for some hands on show & tell lest you experience nuthin' but surprises.